1. Nyamu lembe ma juyubu

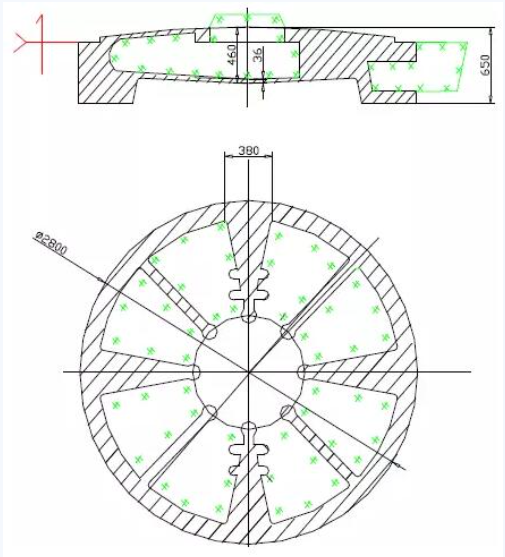

(1) Enibutterfly valveutiye ku kit ma nen calu mugati, vur ma iye ucungo man ucungo ku 8 reinforcing ribs, vur ma malu Φ620 weco ku vur ma iye, man mukende pavalveubedo cego, the sand core tek ni yiko man yot ni loko. Woth pa yamo man yweyu pa vur ma iye kelo peko madit, calu ma ju nyuthu i cal mir acel.

Lak pa cel pa castings lokore lee, lac pa cel ma dit tuc 380mm, man lac pa cel ma piny uromo 36mm kende. Ka casting ubedo matek, tung tung mi lyethu ubedo malac, man shrinkage ma rwinyo copo nyayu shrinkage cavities man shrinkage porosity defects, ma copo kelo pii ma mol i hydraulic test.

2. Yub pa yub:

(1) Kabedo ma jupoko kudu nen i cal mir acel. Keth ajikine ku vur iwi sanduku ma malu, tim sand core i dyere, man i med core head maber pi konyo ketho sand core man woth pa sand core ka box ne utur. Ma tek, bor pa cantilever core head pa vur ario ma nen ungo i thenge bor uloyu bor pa hole, kara center of gravity pa sand core zoo ubed ma ucungo i thenge pa core head ni neno ni sand core ubedo ma ucungo man ma ucungo.

Jutiyo ku yore mi pongu piny ma cego, ∑F iiye: ∑F yo piny: ∑F thwol=1:1.5:1.3, sprue tiyo ku ceramic tube ku diameter ma iiye pa Φ120, man dul aryo pa 200×100×40mm ma tek pa bricks juketho piny pi gwoko iron kud utur sand mold, 150×150×40 foam ceramic filter juketho piny pa runner, man 12 ceramic tubes ku diameter mi iye pa Φ30 jutiyo kudu pi inner runner ni mako piny pa casting nikadhu kud i tank mi pii ma piny pa filter ni yubu bottom pouring calu ma nen i cal mir 2

(3) Keth 14 ∮20 cavity air holes i upper mold, ket Φ200 sand core vent hole i kind core head, ket cold iron i thenge ma gwai man ma dit ni neno ni casting ubedo matek, man ti ku graphitization expansion principle ni juku The feeding riser is used to improve the yield process. Dit pa sand box utiye 3600×3600×1000/600mm, man juyike ku 25mm mi steel plate mi bedo ku tego man tek, calu ma ju nyuthu i cal mir 3.

3. Gwoko tic

(1) Modeling: Mapodi itimo modeling, ti ku Φ50×50mm standard sample pi temo tego pa resin sand ≥ 3.5MPa, man iket cold iron man runner ni neno nia sand mold utiye ku tego ma romo juku graphite ma wok ka molten iron doko tek, man gengo remo kud i molten runner part pi kare malac mi kelo lwoko lum.

Yubu core: The sand core jupoko i dul 8 marom ku 8 reinforcing ribs, ma gicokiri nikadhu kud i kind cavity. Piny mukende ma kony man mi wodhu yamo epe, mako wic mi dyere. Ka sand core copo bedu ngo maber man Exhaust, sand core displacement man air holes biwok ingey pongu. Pien kabedu pa sand core utiye malac, jupoko i dul abora. Umitu obed ku tego man tek ma romo ni neno nia theng lum kud unyothere ingey wodhu mold, man kud unyothere ingey pongo. Deformation timere, kara ebed ku rwom marom pa cel pa casting. Pi the lembe eni, watimo core bone moko ma pire tek, man watweyo iwi core bone ku thwol mi yweyo pi kwanyo yamu kud i core head pi ni neno nia sand mold ubedo ma nyap ka wabe timo core. Calu ma ju nyuthu i cal mir angwen.

(4) Sanduku mi cego: Ka waparu niya etung ni yweyu lum i iye pa butterfly valve, lum zoo juyike ku rangi ario, rangi mir acel juyike ku rangi mi zirconium (Baume degree 45-55), man rangi mir acel juwiro man juwango. I ngei lwoko, ruk dul mir aryo ku rangi magnesium ma tiye ku kongo (Baume degree 35-45) mi juku rangi kud ucung iwi lum man utur, ma jucopu lwoko ngo. Thenge ma pire tek ucungo iwi Φ200 steel pipe pa core bone ku M25 screws adek, juketho man jugwoko ku upper mold sand box ku screw caps man jubedu ka neno ka rwom pa dul acel acel utiye marom.

4. Yore mi lwoko man pongu

(1) Ti ku Benxi low-P, S, Ti high-quality Q14/16# pig iron, man imed i ratio pa 40%~60%; piny ma nok calo P, S, Ti, Cr, Pb, man mange. jugwoko maber in steel ma jucaku kudu, man juyiyu ngo nya nya man moo, wel mi medu utiye 25%~40%; charge ma judwoko umaku juyike ku shot blasting mapodi jutiyo kudu pi neno nia charge ne leng.

(2) Jam tic ma pire tek ingey furnace: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (residual): 0.035% ~0.05%, the premisation of the premisation, under the susid, the susidization. rwom ma piny pa Mg (ma udong) umaku juter madwong akeca.

(3) Spheroidization inoculation treatment: low-magnesium man low-rare-earth spheroidizers jutiyu kudu, man wel mi medo ubedo 1.0%~1.2%. Yore macon mi lwoko spheroidization, 0.15% pa inoculation ma jutimo wang acel juketho iwi nodulizer piny pa jeni, man spheroidization uthum. Slag ne dong jupoko pi 0.35%, man flow inoculation pa 0.15% jutimo i saa mi pongo.

(5) Yore mi pongo pii iwi piny ma ngic ma nok jutiyo kudu, lyethu mi pongo ubedo 1320°C~1340°C, man kare mi pongo ubedo 70~80s. Cuma ma mol copo ngo ni turo ikare ma jucwalo, man sprue cup pongu kare ku kare mi juku gas man piny ma juketho i mold ni kadhu kud i runner. vur.

5. Adwogi pa pima mi timo

(1) Tem tego pa piny ma jucwalo: 485MPa, elongation: 15%, Brinell hardness HB187.

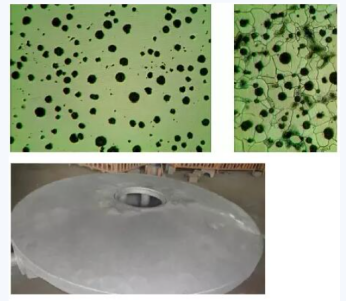

(2) Spheroidization rate utiye 95%, dit pa graphite utiye grade 6, man pearlite utiye 35%. Kit ma metallographic nen kudu nen i cal mir 5.

(3) Peko moko ope ma ju nwango i UT man MT mi nwangu peko mir arionde pa piny ma pire tek.

(4) Kite ma nen kudu ubedo mafoth man mafoth (nen cal mir 6), manangu epe ku peko mi cwio calu lum, lum, cold shuts, man mukende mapol, rwom pa cel ubedo marom, man dit pare urombo ku yeny pa cal.

(6) 20kg/cm2 hydraulic pressure test ingey timo tic unyutho ngo nia pii wok

6. Ajiki

Nimakere ku kit pa butterfly valve eni, peko mi lokore ma yot man ma yot pa sand core madit i dyere man yweyu sand ma tek juyike ku ketho cwiny ikum yub pa yub, yubu man yiku sand core man tic ku zirconium-based coatings. Kethu vur mi yamo jwigo bedo pa vur i castings. Nicaku i furnace charge control man runner system, foam ceramic filter screen man ceramic ingate technology jutiyu kudu pi neno leng pa molten iron. I ngei timo yath madwong, kit ma juyubu ku cuma man lembe matung tung. Tic maber udaru tuc ikum yeny pa juruwil

Kud iTianjin Tanggu Water-seal valve Co.,ltd. Butterfly valve, gate valve, Y-strainer, wafer dual plate check valveyubu.

Saa mi kyewo: Apr-29-2023