Kethu maber pabutterfly valvepiretek pi tic pare mi mako piny man kwo pare mi tic. Karatasi eni nyuthu yore mi ketho piny, lembe ma pire tek, man nyuthu tung tung ma nuti ikind kit piny aryo: wafer-style manflanged butterfly valves. Wafer-style valves, ma juketho ikind pipeline flanges aryo ku tic ku stud bolts, utiye ku yore mi kethu ma tek. I ayi pa tung tung, flanged butterfly valves bino ku flanges ma rwate man jutwo gi directly i mating pipeline flanges, ma weko tic doko yot.

Flange bolts pi wafer butterfly valve utiye mabor. Bor migi ju kwanu ni: 2x lac pa flange + lac pa valve + 2x lac pa nut. Eni utiye pilembe wafer butterfly valve kende epe ku flanges. Ka juwodho bolts man nuts eni, pipelines ma ni thenge ario zo pa valve bibedo marac man ecopo timo ngo tic maber.

Flanged valves tiyo ku bolts ma nok, ku bor ma juloko ni 2x flange thickness + 2x nut thickness, mi mako flanges pa valve gire direct ku ma ni i pipeline. Ber pa yub eni utiye nya eweko thenge acel jupoko manangu eturo ngo tic pa pipeline mukende.

Lembe maeni bi nyuthu kite mi ketho wafer butterfly valves kuTWS.

Wafer butterfly valve utiye ku kit ma yot, ma nok, man ma pek ungo ku piny manok kende. Etiyo ku 90° ma lokore pio pio, ma weko bedo yot pa on/off control man miyo rwom maber pa pii.

I. Lembe ma umitu jutim ma podi ju ketho ngoWafer-Type Butterfly Valve

- Mapodi jucaku ketho, pipeline umaku juyik piny moko ci ma woko ku yamo ma juku man juyike ku pii maleng.

- Nen maber ka tic pa valve urombo ku lembe ma jukwanu (lyet, tegu).

- Nen kama valve ucungo i iye man kabedo ma juketho iye cinge pi lembe moko marac, man iwoth woko pio pio.

- I ngei wodhu piny, valve umaku juket pio pio. Kud iwek cing moko ci ma mako valve nyoke nuts iwi valve.

- Butterfly valve flange ma juyiko pi wafer type butterfly valves umaku juti kudu.

- Kuvalve mi butterfly pa macecopu bedu iwi paip i thenge moku ci, ento pi gwoko yot, juwacu ni kud ikethe piny.

- Ka ibe ketho butterfly valve flange, piretek ni neno nia wang flange man rubber mi juku utiye marom, bolts ucungo maber, man kabedo mi juku umaku ubed maber. Ka bolts ne ucungo ngo maber, ecopu ketho rubber ucung man ucung disc, nyo ucwalu disc, ma kelo leakage i valve stem.

II.Kethu: Wafer Butterfly Valve

Mi neno nia jamb tiyo maber man maber pa butterfly valve, lub yore mi kethu piny eno piny eno.

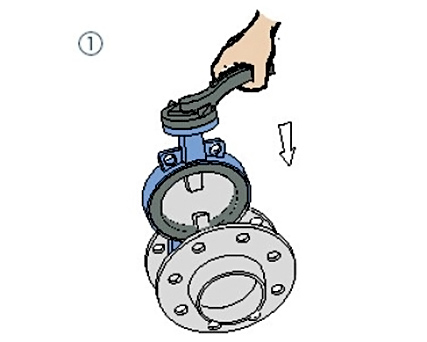

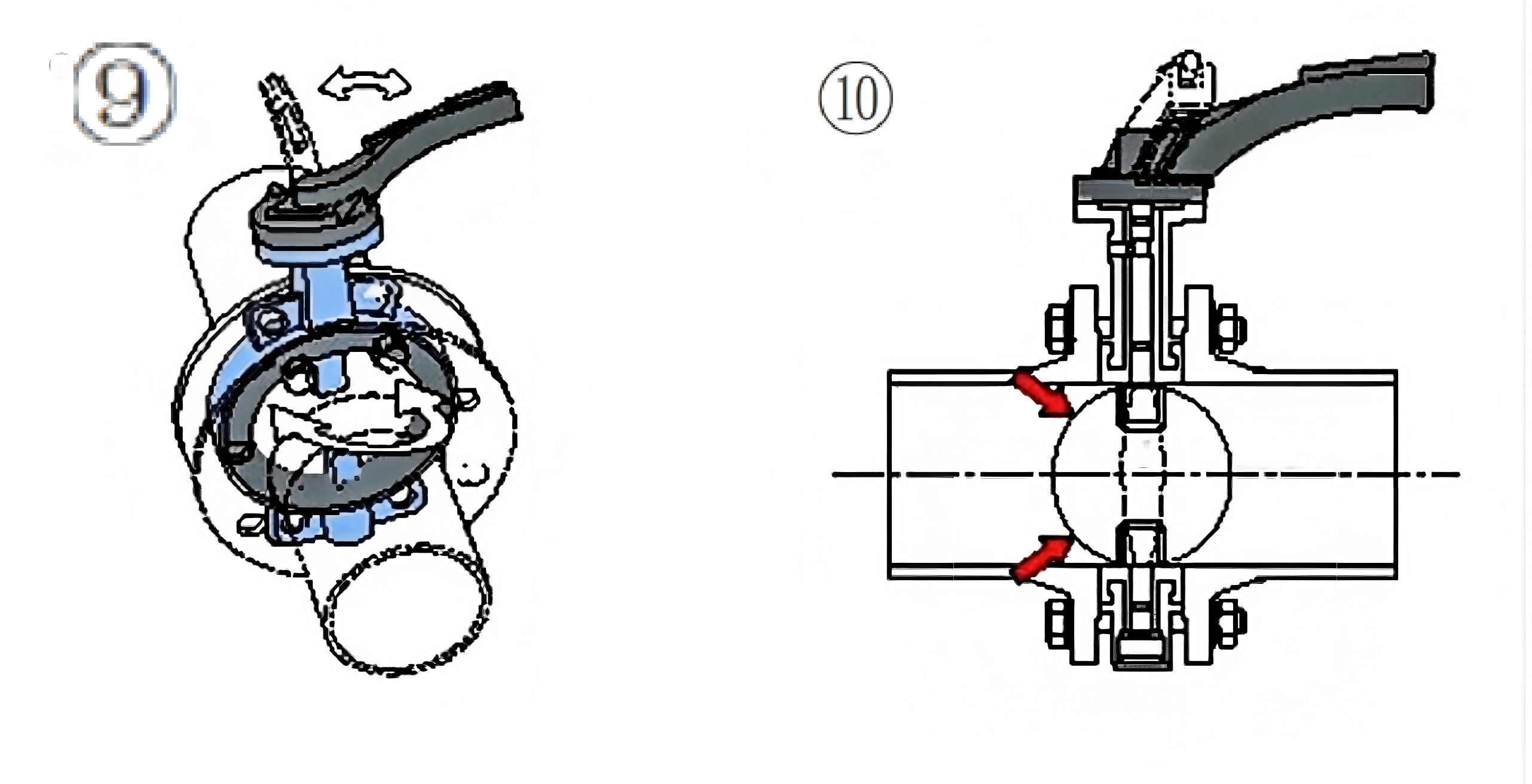

1. Calu ma ju nyuthu, ket valve ikind flanges aryo ma ju ketho con, nen nia bolt holes utiye maber.

2. Med bolts angwen ku nuts i vur mi flange, man iket nuts ne matek pi yiko flange pa flange;

3. Ti ku spot welding mi ketho flange i pipeline.

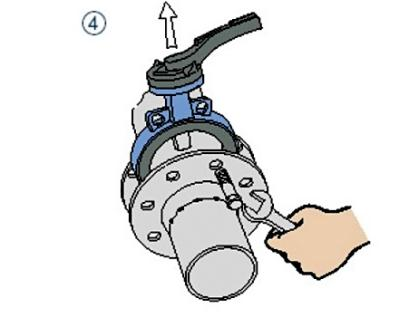

4. Woth valve;

5. Weld flange ikum pipeline.

6. Keth valve kende kende ingey welded joint udaru ngic. Nenu nia valve utiye ku kabedu muromo mi wothu i flange pi jwigo ret man nia valve disc copo yabere i kadhiri moku.

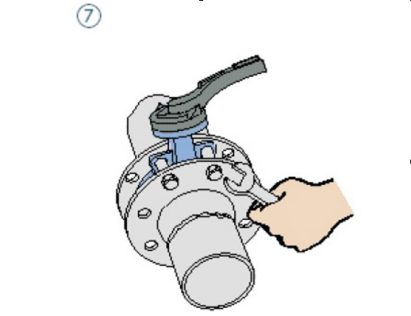

7. Lok kabedo pa valve man iket bolt angwen (bed ma ling kara kud iket tek akeca).

8. Yab valve ni neno nia disc copo wotho maber, man iyab disc nyanok.

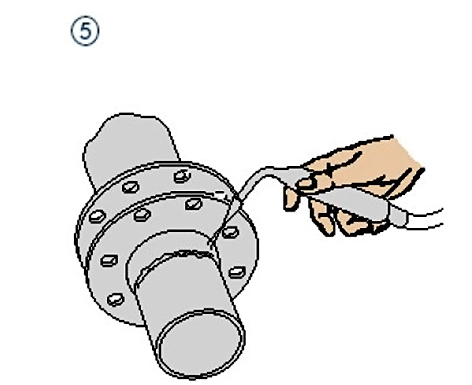

9. Ti ku lanyuth pa cross pi mako nuts zo.

10. Keth kendu kendu nia valve copo yabere man cego maber. Poi: Bed ma ingeyo nia valve disc umulo ngo pipeline.

Pi tic maber man ma pii unyai ungo pa wafer butterfly valves, lubu cik ma e:

- Ti kude maber: Gwok valve maber man kud ibed ku peko.

- Keth maber: Neno ni flange ubedo maber pi jwigo pii.

- Kud ipok: Ka dong ikete, valve umitu kud ipok i podho.

- Keth piny ma kony ma rii: Gwok valve ku kony ma umitu obed kakare.

TWSmiyo butterfly valves maber man yore maber mivalve mi dhugola, check valve, manvalves mi wodhu yamu. Wec kudwa pi yeny peri mi valve.

Saa mi cwalo: Nov-08-2025